Concrete Scanning in Wollongong

- Over 25 Years of Underground Locating Expertise

- Free, No-Obligation Quotes

- Certified, Accredited & Fully Insured

Request A Call Back

Thank you for contacting Dowds Pipe and Cable Locating.

We will get back to you as soon as possible.

Oops, there was an error sending your message.

Please try again later.

Wollongong Concrete Scanning

Locating embedded elements within concrete requires precision, experience and the right technology.

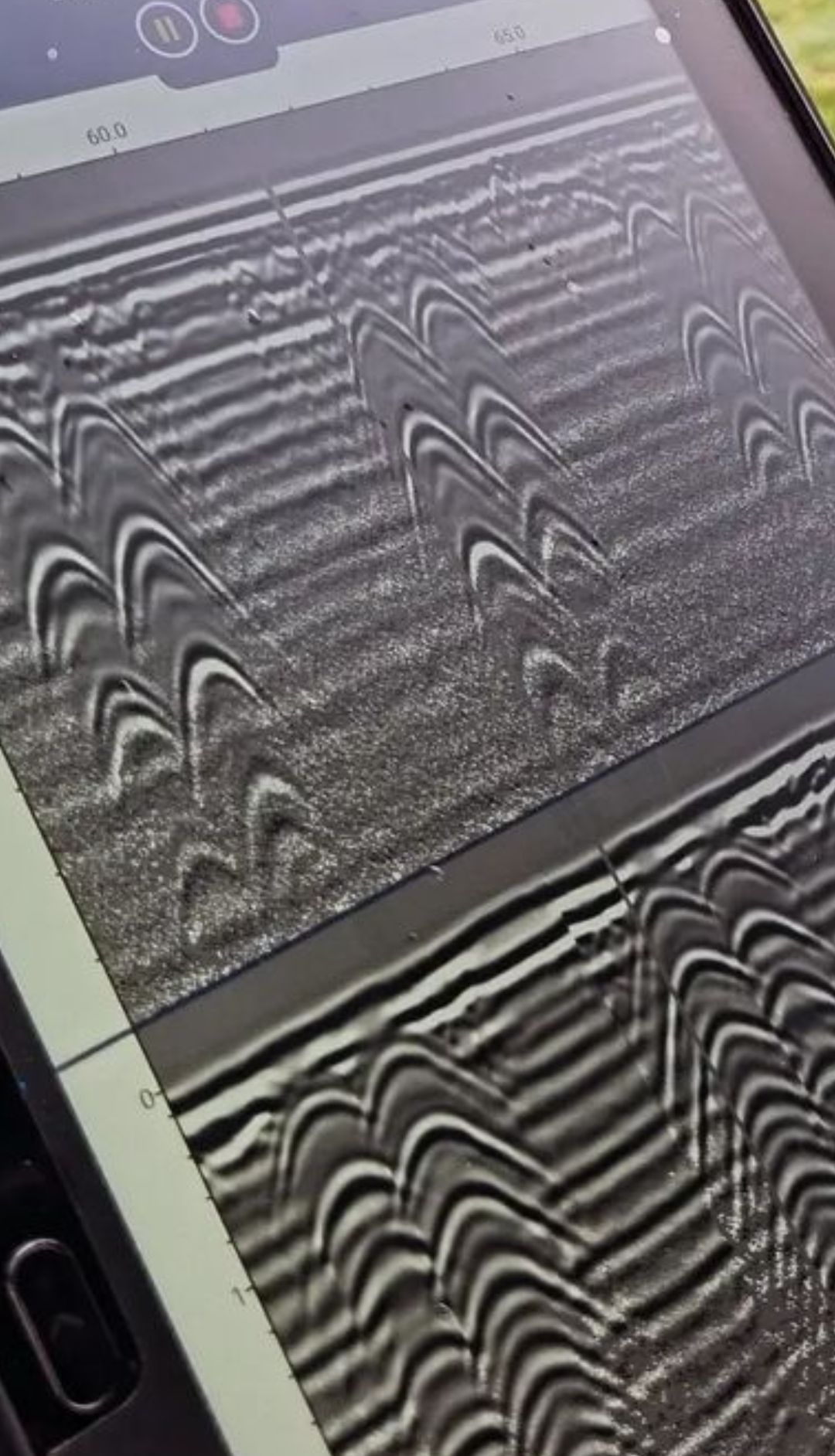

At Dowd’s Pipe and Cable Locating, based in Wollongong, we apply advanced ground-penetrating radar (GPR) systems to detect rebar, conduits, post-tension cables and voids before cutting or coring begins. This non-destructive method is a cornerstone of safe, compliant construction and renovation practices—particularly where structural integrity is critical.

Whether you’re managing a multi-storey development or residential retrofit, our concrete scanning process supports decision-making with real-time, high-resolution data and reduces the risk of costly damage, repair delays and safety hazards.

By prioritising accurate subsurface data, our team helps engineers, builders and contractors proceed with clarity. For site-specific advice or a no-obligation quote, call 0434 63 5134.

How Concrete Scanning Supports Construction Safety

Concrete scanning plays a critical role in project planning, construction safety and compliance with national standards. Using high-frequency radar technology, our technicians conduct targeted scans that provide cross-sectional images of concrete up to several hundred millimetres deep. This allows for the identification of structural and non-structural elements before excavation or drilling.

Applications include suspended slabs, walls, footings, columns and concrete-encased services—each requiring a tailored approach based on depth, material density, and known risk factors.

As part of our integrated asset locating services, concrete scanning is often conducted in tandem with pipe and cable locating to provide a full utility profile of the site. The end result is a safer work environment, fewer disruptions and compliance with construction codes and WHS requirements.